Ethylene polymers are thermoplastic polymers which are utilized in the generation of different packaging materials. These polymers (particularly the ones referenced underneath) have great protection from alcohols, oils, acids and salts. A standout amongst the most imperative highlights of this kind of material with regards to packaging is that it has great obstruction properties to oxygen and carbon dioxide which makes is appropriate for food stuff packaging.

Given below is the depiction of some regular ethylene polymers utilized in different structures, particularly for the packaging of transient consumer things (foodstuff and pharmaceuticals).

Ethylene Vinyl Acetate (EVA)

This is known as froth elastic with properties such as flexibility, versatility, transparency, great low temp adaptability and high grinding co-effectiveness. EVA is utilized basically as a cushioning material in the packaging containers for example, gadgets and many more.

Ethylene Vinyl Alcohol Copolymer (EVOH)

This is a formal copolymer of ethylene and vinyl liquor. It is utilized as a high obstruction material to gases (O2 and CO2) yet is a low dampness vapor hindrance material. These properties reduce in a damp domain. This is a costly packaging material. Broadly utilized as an obstruction film in an overlay, EVOH is utilized principally for good packaging and typically as a dainty layer inside cardboard or foil, to improve the time span and usability of the food packaged.

High Density Polyethylene (HDPE)

HDPE is a polyethylene thermoplastic produced using oil. It is Semi-unbending, translucent, extremely intense, and furthermore has low water retention. HDPE has moderate obstruction properties yet isn’t appropriate for use at high temperatures. It is generally blow shaped to frame delicate jugs, for example to store milk, cleansers, and so on. It offers ease and a very effectively created material.

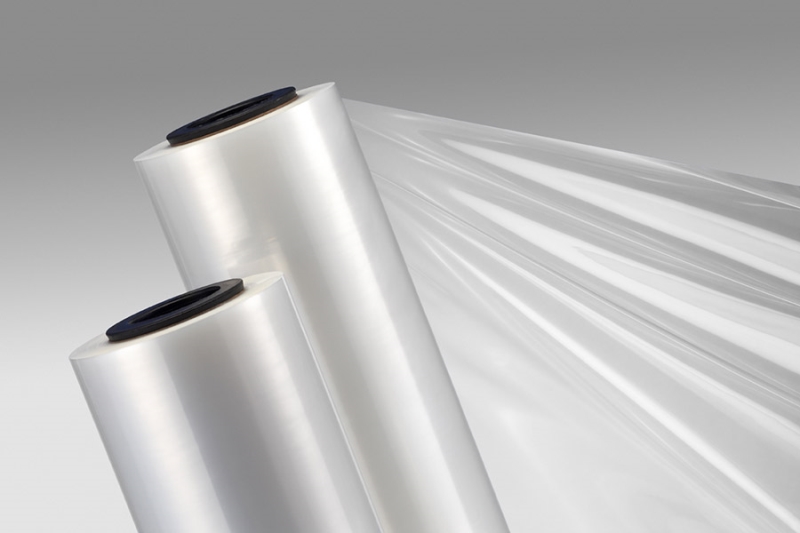

Low Density Polyethylene/Linear Low Density Polyethylene (LDPE – LLDPE)

LDPE is a thermoplastic produced using oil. It is strong yet adaptable, waxy, dampness/climate-proof, has great low temperature durability and is anything but difficult to process by most techniques with ease and has great obstruction and moderate boundary properties. It is broadly utilized for its warmth fixing properties in a covered material. It isn’t reasonable for use at temperatures above 100° C and is recyclable. It is additionally consumption safe. These properties make it suitable for the generation of broadly useful compartments for foodstuffs.

Polyethylene Terephthalate (PET or PETE)

PET is a thermoplastic polymer sap and is utilized in engineered filaments. PET Films are chemically treated and are unbending, incredibly safe, have great killjoy and exhaustion opposition, wide range temperature obstruction (- 40 to 220° C) and does not stream on warming. These films are widely utilized to manufacture containers for carbonated beverages and solvents in the light of their good resistance and barrier properties. These films are also very easy to recycle, and this attribute makes it an absolutely very environment friendly packaging material.